Verifying test of corrosion resistant steel in cargo oil tanks in accordance with IMO MSC.289(87) 《Performance Standard For alternative Means Of Corrosion Protection For Cargo Oil Tanks Of Crude Oil Tankers》, including test on simulated inner bottom condition and upper deck condition. The estimated corrosion loss after 25years, ECL, shall be ≤2mm and the corrosion rate after 72 hours immersion, C.R.ave, shall be≤1.0mm/a. Meanwhile, the corrosion loss, CL, of conventional steel for reference after 98 days, shall be between 0.05-0.11.

| Test |

Test Item |

Investigation Item |

| Test on simulated inner bottom conditions |

According to IMO MSC 289(87),the test solution contains 10 mass% NaCl and its pH is 0.85 adjusted by HCl solution. The test solution should be changed to a new one every 24h to minimize pH change of the test solution. The temperature of the test solution is to be kept at (30±2)℃. The test shall be carried out for 72h. |

The weight loss shall be investigated |

|

Test on simulated upper deck conditons |

According to IMO MSC 289 (87) ,simulating the condition of the actual upper deck, the test cycle runs with distilled water and simulated COT gas(4±1)% O2,(13±2)% CO2,(100±10)ppm SO2,(500±50)ppm H2S,(83±2)% N2); the time for one cycle is 24h, the temperature of the distilled water is to be kept at not higher than 36℃. |

The weight loss shall be investigated |

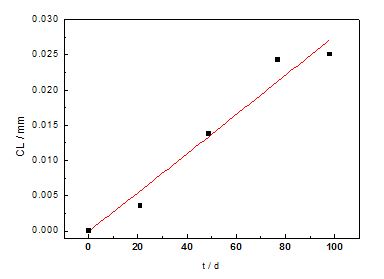

Amount of atmosphere corrosion resisting steel corrosion test of variation over time

- 168 Nei'an zhong lu, Xiang'an, Xiamen, Fujian, China

- 0592-7258803

- 18060932725

- 1212@qq.com coatingtest@163.com